- Home

- Microsoft

- Microsoft Dynamics 365 Supply Chain Management Functional Consultant

- Microsoft.MB-330.v2025-03-21.q154

- Question 94

Valid MB-330 Dumps shared by ExamDiscuss.com for Helping Passing MB-330 Exam! ExamDiscuss.com now offer the newest MB-330 exam dumps, the ExamDiscuss.com MB-330 exam questions have been updated and answers have been corrected get the newest ExamDiscuss.com MB-330 dumps with Test Engine here:

Access MB-330 Dumps Premium Version

(495 Q&As Dumps, 35%OFF Special Discount Code: freecram)

<< Prev Question Next Question >>

Question 94/154

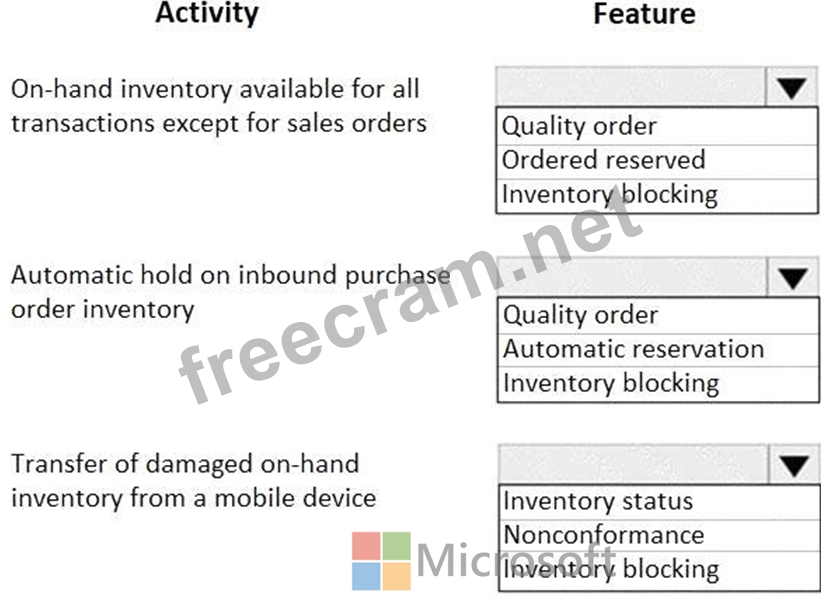

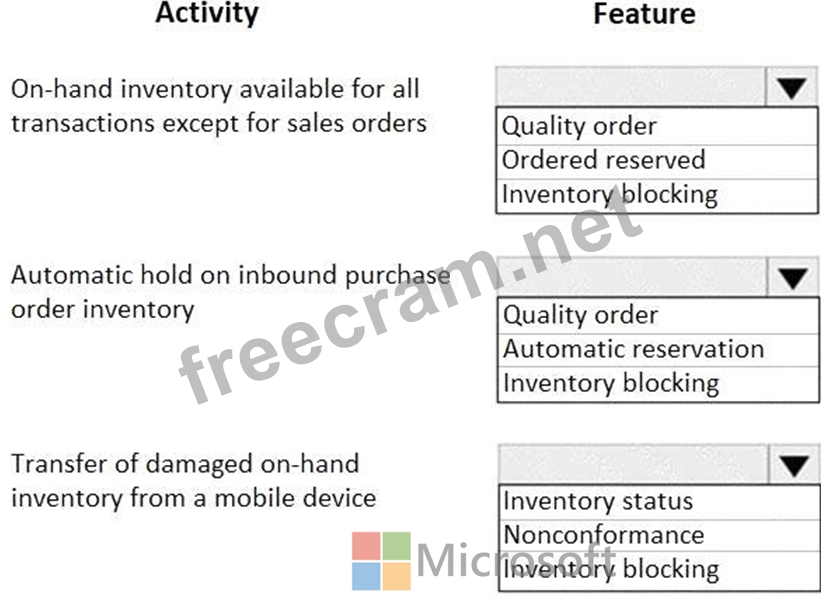

A company implementing Dynamics 365 Supply Chain Management has multiple warehouses, some of which are Warehouse Management-enabled.

The company must hold inventory for the following purposes:

* On-hand inventory available for all transactions except for sales orders.

* Automatic hold on inbound purchase order inventory.

* Damaged on-hand inventory that can be transferred from a mobile device, leaving the undamaged inventory available.

You need to determine the feature that applies to each company requirement.

Which features should you use? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

The company must hold inventory for the following purposes:

* On-hand inventory available for all transactions except for sales orders.

* Automatic hold on inbound purchase order inventory.

* Damaged on-hand inventory that can be transferred from a mobile device, leaving the undamaged inventory available.

You need to determine the feature that applies to each company requirement.

Which features should you use? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

Correct Answer:

Explanation:

Box 1: Ordered reserved

On-hand inventory available for all transactions except for sales orders.

Query your on-hand inventory

To check the availability of inventory, go to Inventory management > Inquiries and reports > On-hand list.

The On-hand list page is automatically updated when transactions are made in inventory. Those transactions might be forecasted, physical, or financial transactions.

For each matching item, the On-hand grid provides the following columns of inventory information.

* Ordered reserved - The total quantity that is reserved on ordered receipts. The value in this field represents the total quantity of items in outbound transactions that have a status of Ordered reserved. Items that are reserved as ordered aren't physically available in inventory. Therefore, they can't be directly picked and delivered.

* Etc.

Box 2: Inventory blocking

Automatic hold on inbound purchase order inventory.

Inventory blocking is part of the quality inspection process in Supply Chain Management. You can use inventory blocking to prevent items from being processed or consumed.

You can block inventory items in the following ways:

Manually

By creating a quality order

By using a process that generates a quality order

By using inventory status blocking

Box 3: Inventory status

Damaged on-hand inventory that can be transferred from a mobile device, leaving the undamaged inventory available.

Set up and use inventory statuses

You can use inventory statuses to categorize inventory. You can then initiate appropriate actions, such as replenishment or put-away work.

Here are some examples of ways that you can use inventory statuses:

Create inventory statuses for on-hand inventory, inbound transactions, and outbound transactions.

Specify a default inventory status for warehouse transactions.

Change an inventory status for items before arrival, during arrival, or when the items are put away during inventory movement.

Use an inventory status to price items that are returned and to plan item coverage during master planning.

Incorrect:

* Quality Order

The Quality management for warehouse processes feature lets you integrate item sampling controls into the warehouse receiving process by using warehouse management processes (WMS). Warehouse work can be automatically generated to move inventory to the quality control location, based on a percentage or a fixed quantity, or based on every nth license plate. After a quality order has been completed, work can be automatically generated to move inventory to the next location in the process, depending on the quality results.

The Quality management for warehouse processes feature extends the capabilities of the basic quality management feature. It provides the option to create quality orders for the inventory that is sent to the quality control location, although quality orders aren't always required. Therefore, it allows for a lightweight quality control process that is based on warehouse work.

* Nonconformance

A nonconformance describes an item that has a quality problem. The nonconformance process lets you create a nonconformance order that describes a quantity of nonconforming material, the problem source, the problem type, and explanatory notes.

Reference: https://learn.microsoft.com/en-us/dynamics365/supply-chain/inventory/inventory-on-hand-list

https://learn.microsoft.com/en-us/dynamics365/supply-chain/inventory/quality-management-for-warehouses- processes

https://learn.microsoft.com/en-us/dynamics365/supply-chain/inventory/inventory-blocking

- Question List (154q)

- Question 1: You need to enable the automatic firming of planned orders f...

- Question 2: A company has items in inventory with two costing methods: F...

- Question 3: Note: This question is part of a series of questions that pr...

- Question 4: A company uses Dynamics 365 Supply Chain Management master p...

- Question 5: You are the warehouse manager at a distribution center. In t...

- Question 6: A company uses Dynamics 365 Supply Chain Management. Sales o...

- Question 7: You need to configure the system for the customer tier B pri...

- Question 8: You need to define where the tires should be put away in the...

- Question 9: A company uses Dynamics 365 Supply Chain Management to manag...

- Question 10: You are a functional consultant for a company named Contoso ...

- Question 11: You are a functional consultant for a company named Contoso ...

- Question 12: A primary vendor tells you that their purchase order (PO) it...

- Question 13: Note: This question is part of a series of questions that pr...

- Question 14: A company uses the built-in Dynamics 365 Supply Chain Manage...

- Question 15: You need to consolidate orders and prepare to rate shop ship...

- Question 16: All items that a company purchases from a specific vendor ar...

- Question 17: A company uses Dynamics 365 for Finance and Operations. A cu...

- Question 18: A company uses Dynamics 365 Supply Chain Management. You nee...

- Question 19: A company that has two legal entities is implementing Dynami...

- Question 20: You need to configure inventory levels for the retail stores...

- Question 21: You need to configure the system to meet the item testing re...

- Question 22: A distribution company implementing Dynamics 365 Supply Chai...

- Question 23: You are a functional consultant for a company named Contoso ...

- Question 24: You need to configure the system to support regional sales r...

- Question 25: A client wants to use Dynamics 365 for Finance and Operation...

- Question 26: A distribution company that Dynamics 365 Supply Chain Manage...

- Question 27: You are setting up safety margins. Which unit of measure is ...

- Question 28: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 29: A company needs to be alerted when the calculated planned co...

- Question 30: A company plans to create purchase agreements in the system ...

- Question 31: You are the warehouse manager at a large distribution compan...

- Question 32: You need to configure the pricing for the white-labeled prod...

- Question 33: A distribution company uses Dynamics 365 Supply Chain Manage...

- Question 34: You need to configure the system to meet the metric requirem...

- Question 35: A manufacturing company has implemented Dynamics 365 Supply ...

- Question 36: A company uses outside carrier services for inbound and outb...

- Question 37: You are a functional consultant for a company named Contoso ...

- Question 38: You need to enable the system to correctly calculate vendor ...

- Question 39: A company is implementing Dynamics 365 Supply Chain Manageme...

- Question 40: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 41: You need to set up reordering for new items. Which two actio...

- Question 42: A company requires that a percentage of the building overhea...

- Question 43: Note: This question is part of a series of questions that pr...

- Question 44: You need to configure automated testing for the following ta...

- Question 45: :118 HOTSPOT A parent company owns two subsidiaries. Some of...

- Question 46: You are the customer relations manager at a wholesale compan...

- Question 47: A company is implementing Dynamics 365 Supply Chain Manageme...

- Question 48: A company allows negative inventory because they ship outbou...

- Question 49: A company plans to stock new items and value those items by ...

- Question 50: A company uses Dynamics 365 for Finance and Operations. An e...

- Question 51: A company is evaluating sales pricing strategies in a costin...

- Question 52: A manufacturer of a bill of materials (BOM) part that is use...

- Question 53: During a company's busy season, the sales team experiences m...

- Question 54: A company plans to use Dynamics 365 for Finance and Operatio...

- Question 55: A company uses planning optimization in Dynamics 365 Supply ...

- Question 56: An employee at a company releases a new product from the Rel...

- Question 57: You are the sales manager at a distribution company. You hav...

- Question 58: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 59: You are the inventory manager for a distribution center. You...

- Question 60: An employee at a company needs to lay out the various compon...

- Question 61: A cosmetics company uses Dynamics 365 Supply Chain Managemen...

- Question 62: You are a functional consultant for a company named Contoso ...

- Question 63: A company uses procurement in Dynamics 365 Supply Chain Mana...

- Question 64: You need to implement location directives in Dynamics 365 fo...

- Question 65: You need to complete the shipments. What should you do?...

- Question 66: A company uses Dynamics 365 for Finance and Operations. You ...

- Question 67: You need to configure the extreme sports discounts. Which co...

- Question 68: Note: This question is part of a series of questions that pr...

- Question 69: You create and maintain items in Dynamics 365 Supply Chain M...

- Question 70: You are a functional consultant for a company named Contoso ...

- Question 71: A company uses Dynamics 365 Supply Chain Management to sell ...

- Question 72: You need to determine the costing versions for the requireme...

- Question 73: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 74: A company is implementing the Warehouse management module in...

- Question 75: You are the product manager at a distribution company. You a...

- Question 76: :117 Note: This question is part of a series of questions th...

- Question 77: A company uses Dynamics 365 Supply Chain Management for inve...

- Question 78: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 79: You need to reduce the fulfillment team's workload. Which fo...

- Question 80: You plan to use Planning Optimization. You configure a recei...

- Question 81: A retail distributor is implementing Dynamics 365 Supply Cha...

- Question 82: Note: This question is part of a series of questions that pr...

- Question 83: A company uses Dynamics 365 Supply Chain Management and has ...

- Question 84: A company uses several freight carriers. Freight is calculat...

- Question 85: A company is implementing inventory by using Dynamics 365 Su...

- Question 86: You need to resolve the issue for UserB? Which options shoul...

- Question 87: You need to configure the system to support the pottery prod...

- Question 88: Inventory in a warehouse is assigned to an inventory status ...

- Question 89: A company plans to use the Planning Optimization add-in. How...

- Question 90: A company needs to calculate the cost for a group of bill of...

- Question 91: A company uses Dynamics 365 Supply Chain Management to manag...

- Question 92: A manufacturing company uses Dynamics 365 Supply Chain Manag...

- Question 93: A frozen food distribution company is implementing Dynamics ...

- Question 94: A company implementing Dynamics 365 Supply Chain Management ...

- Question 95: A company uses Dynamics 365 Supply Cham Management to manage...

- Question 96: Note: This question is part of a series of questions that pr...

- Question 97: A company uses Dynamics 365 Supply Chain Management with bas...

- Question 98: You are implementing Dynamics 365 Supply Chain Management fo...

- Question 99: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 100: A client uses Dynamics 365 Supply Chain Management. You need...

- Question 101: A buyer places a purchase requisition for item C0001 from a ...

- Question 102: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 103: A customer service agent creates a sales order for a custom ...

- Question 104: A company is using advanced warehouse functionality in Dynam...

- Question 105: You need to configure the system for the new products that t...

- Question 106: An e-commerce retail company is implementing Dynamics 365 Su...

- Question 107: A company orders parts from a vendor. The vendor frequently ...

- Question 108: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 109: A company uses Planning Optimization as a scheduled batch jo...

- Question 110: A company creates a new bill of materials (BOMs). The compan...

- Question 111: A company has several warehouse locations. The company acqui...

- Question 112: You need to process the expedited photocopier replacement. W...

- Question 113: A company with two legal entities uses Dynamics 365 Supply C...

- Question 114: A company uses Dynamics 365 Supply Chain Management. The wor...

- Question 115: A manufacturing company uses Planning Optimization. Manned p...

- Question 116: :115 Note: This question is part of a series of questions th...

- Question 117: A company is implementing Dynamics 365 Supply Chain Manageme...

- Question 118: A company implements the Dynamics 365 Supply Chain Managemen...

- Question 119: You are implementing warehousing in Dynamics 365 for Finance...

- Question 120: You must configure pen flash sale prices. What should you co...

- Question 121: You are a functional consultant for a company named Contoso ...

- Question 122: A distribution company uses Dynamics 365 Supply Chain Manage...

- Question 123: A retailer that uses Dynamics 365 Supply Chain Management is...

- Question 124: A company is designing a new bicycle by using a dimension-ba...

- Question 125: A company is implementing Dynamics 365 Supply Chain Manageme...

- Question 126: You need to order the high-end tires. What should you set up...

- Question 127: A company uses Dynamics 365 for Finance and Operations. You ...

- Question 128: A company is implementing Dynamics 365 Supply Chain Manageme...

- Question 129: Note: This question is part of a series of questions that pr...

- Question 130: You are a functional consultant for a company named Contoso ...

- Question 131: A company manufactures street, mountain, and racing bicycles...

- Question 132: A company uses Dynamics 365 Supply Chain Management. The fin...

- Question 133: :116 Note: This question is part of a series of questions th...

- Question 134: Note: This question is part of a series of questions that pr...

- Question 135: Negotiations with the vendor are complete. You need to set u...

- Question 136: A company creates loads to ship sales orders. Loads must be ...

- Question 137: You need to provide the information for the costing manager....

- Question 138: You need to identify the cause for the inventory issue repor...

- Question 139: A company discovers that the standard cost of a raw material...

- Question 140: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 141: A company uses Planning Optimization. A customer calls a ser...

- Question 142: You need to configure the vendor pricing for pencils. What s...

- Question 143: A company hires four sales representatives for a region name...

- Question 144: You are the logistics manager at a distribution company. You...

- Question 145: You need to configure the bike properties based on the requi...

- Question 146: You need to configure the system to meet the inventory team ...

- Question 147: A manufacturing company is setting up a new warehouse. The w...

- Question 148: A company uses Dynamics 365 Supply Chain Management to manag...

- Question 149: You are setting up safety margins. Which unit of measure is ...

- Question 150: A company uses Dynamics 365 for Finance and Operations and i...

- Question 151: You use Dynamics 365 Supply Chain Management to manage inven...

- Question 152: A distribution company uses Dynamics 365 Supply Chain Manage...

- Question 153: A manufacturing company uses Dynamics 365 Supply Chain Manag...

- Question 154: A company that uses Dynamics 365 Supply Chain Management rec...