- Home

- Microsoft

- Microsoft Dynamics 365 Supply Chain Management Functional Consultant

- Microsoft.MB-330.v2021-10-26.q61

- Question 16

Valid MB-330 Dumps shared by ExamDiscuss.com for Helping Passing MB-330 Exam! ExamDiscuss.com now offer the newest MB-330 exam dumps, the ExamDiscuss.com MB-330 exam questions have been updated and answers have been corrected get the newest ExamDiscuss.com MB-330 dumps with Test Engine here:

Access MB-330 Dumps Premium Version

(495 Q&As Dumps, 35%OFF Special Discount Code: freecram)

<< Prev Question Next Question >>

Question 16/61

Employee 1 needs to set up the new items for the product line

Which two actions should Employee1 perform? Each correct answer presents part of the solution.

NOTE Each correct selection is worth one point.

Which two actions should Employee1 perform? Each correct answer presents part of the solution.

NOTE Each correct selection is worth one point.

Correct Answer: C,E

Topic 1, Organics Company

Background

Best for You Organics Company started as a home-based business. The founders began making handmade soaps and bath products in their kitchen As sales increased, the business established a production facility and distribution center that supplies three retail stores.

Soaps and bath products are manufactured in the production facility and are stocked in the warehouse for distribution to the retail stores. Employees at retail stores use mobile point of sale (MPOS) tablet devices to sell the products to customers.

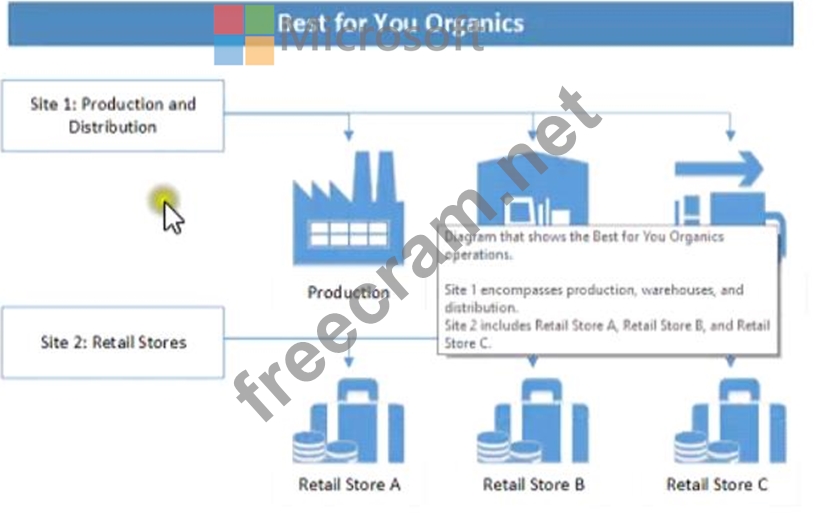

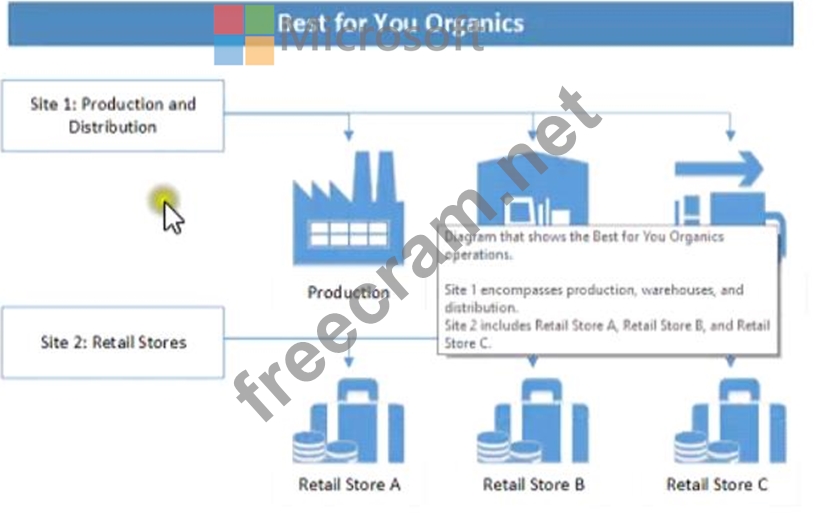

The company structure is a single legal entity with two sites as shown In the diagram below:

Current environment

Best for You Organics plans to introduce a new product line of face creams. Each product in the new line uses the same base ingredients but includes a different extract (for example, lime, avocado, kiwi). The marketing department is preparing to introduce the new product line. Minimal inventory will be held in the warehouse.

The company uses a cloud-based deployment of Dynamics 365 Supply Chain Management to manage finances for all company operations and locations. The company does not use Bill of Materials (BOM) versioning.

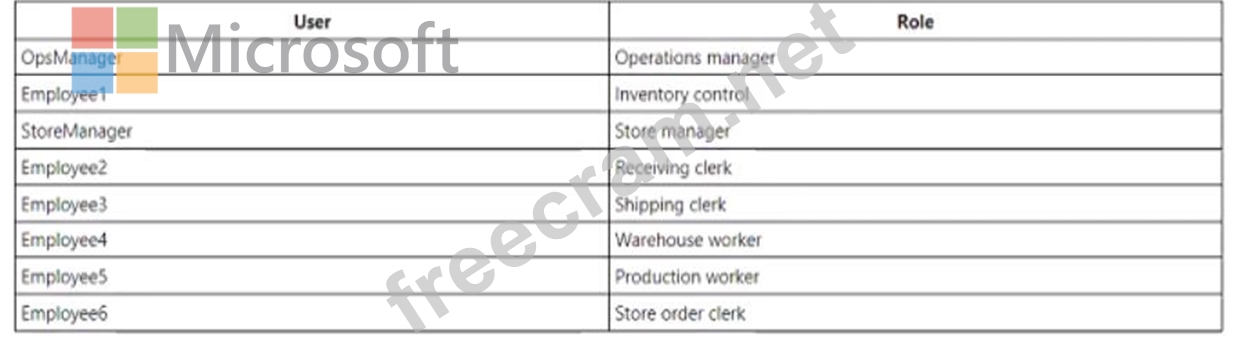

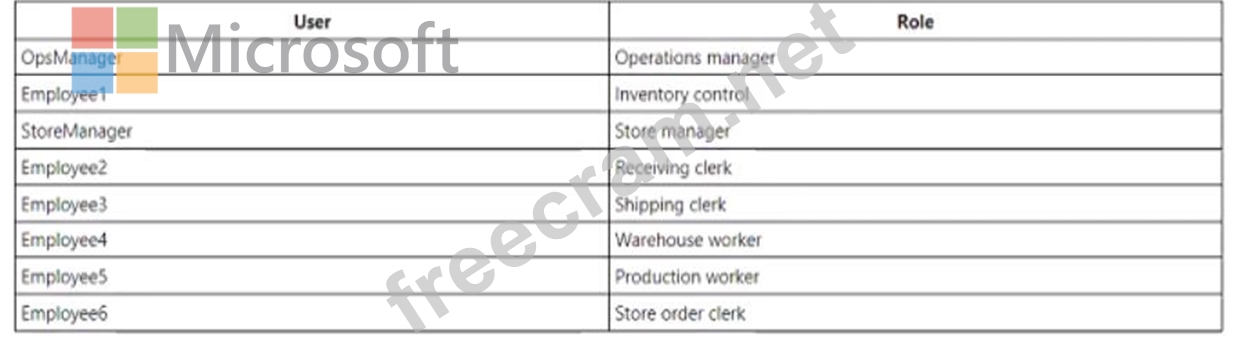

The production and warehouse facility is set up with the following organizational hierarchy:

External customers include:

* Customer A: a walk-in store customer (business-to-consumer)

* Customers: a customer with an existing account (business-to-business) External vendors include:

* VendorA a trucking company

* VendorB: a raw materials supplier

General

The new product line must be set up in the system and readily available for sale when the company introduces the product line to the public at an upcoming trade show.

Production

You must configure the system to produce the new products:

* Ensure that the warehouse stocks the minimum quantities of raw materials to produce the products,

* Use a single version per item.

* Implement FIFO inventory valuation methods.

* Track raw and finished goods using different General ledger accounts.

* Use a primary location to determine where to stock product in the warehouse.

* Configure alternate locations in the warehouse to hold overstock products and refill the primary location as-needed.

Shipments

You identify the following requirements related to shipping:

* Ship product to retail stores weekly.

* Stores require a packing slip to check in merchandise. Drivers require transport documentation and charge per mile to the stores.

* Shipments to Store1 must be scheduled for Monday. Wednesday, or Friday, Store1 will sometimes pick up their own deliveries when an order is small because they have their own van Shipments to Store2 and Store3 must be scheduled for Tuesday or Thursday.

* You must transmit Advance Shipping Notifications (ASNs) to the stores prior to deliveries.

* Set up the system configuration to allow for store transfers.

* Set up the system so that products may be shipped to the retail stores as bulk orders.

* Set up the transport providers to deliver products from the warehouse to the retails stores.

Reporting

Once the new products are available in stores, review 30 days of historical sales data from day-to-day transactions will determine the reorder quantities. Set up reporting to allow the product line to be costed and tracked independent of other items.

Pricing and inventory

You identify the following requirements related to pricing and inventory:

* Determine the Quantity of the new products that can be produced and ready for sale within the first 90 days. Ensure that specialty packaging is on hand for retail sales. The packaging must be shipped directly to the stores from the vendor.

* Stores must not inventory the packaging materials. Stores must maintain a 50-day supply of specialty packaging materials. Stores must reorder packaging materials as needed.

* Retail store customers must pay full retail price, Resellers must receive a 10 percent discount off the list price.

Background

Best for You Organics Company started as a home-based business. The founders began making handmade soaps and bath products in their kitchen As sales increased, the business established a production facility and distribution center that supplies three retail stores.

Soaps and bath products are manufactured in the production facility and are stocked in the warehouse for distribution to the retail stores. Employees at retail stores use mobile point of sale (MPOS) tablet devices to sell the products to customers.

The company structure is a single legal entity with two sites as shown In the diagram below:

Current environment

Best for You Organics plans to introduce a new product line of face creams. Each product in the new line uses the same base ingredients but includes a different extract (for example, lime, avocado, kiwi). The marketing department is preparing to introduce the new product line. Minimal inventory will be held in the warehouse.

The company uses a cloud-based deployment of Dynamics 365 Supply Chain Management to manage finances for all company operations and locations. The company does not use Bill of Materials (BOM) versioning.

The production and warehouse facility is set up with the following organizational hierarchy:

External customers include:

* Customer A: a walk-in store customer (business-to-consumer)

* Customers: a customer with an existing account (business-to-business) External vendors include:

* VendorA a trucking company

* VendorB: a raw materials supplier

General

The new product line must be set up in the system and readily available for sale when the company introduces the product line to the public at an upcoming trade show.

Production

You must configure the system to produce the new products:

* Ensure that the warehouse stocks the minimum quantities of raw materials to produce the products,

* Use a single version per item.

* Implement FIFO inventory valuation methods.

* Track raw and finished goods using different General ledger accounts.

* Use a primary location to determine where to stock product in the warehouse.

* Configure alternate locations in the warehouse to hold overstock products and refill the primary location as-needed.

Shipments

You identify the following requirements related to shipping:

* Ship product to retail stores weekly.

* Stores require a packing slip to check in merchandise. Drivers require transport documentation and charge per mile to the stores.

* Shipments to Store1 must be scheduled for Monday. Wednesday, or Friday, Store1 will sometimes pick up their own deliveries when an order is small because they have their own van Shipments to Store2 and Store3 must be scheduled for Tuesday or Thursday.

* You must transmit Advance Shipping Notifications (ASNs) to the stores prior to deliveries.

* Set up the system configuration to allow for store transfers.

* Set up the system so that products may be shipped to the retail stores as bulk orders.

* Set up the transport providers to deliver products from the warehouse to the retails stores.

Reporting

Once the new products are available in stores, review 30 days of historical sales data from day-to-day transactions will determine the reorder quantities. Set up reporting to allow the product line to be costed and tracked independent of other items.

Pricing and inventory

You identify the following requirements related to pricing and inventory:

* Determine the Quantity of the new products that can be produced and ready for sale within the first 90 days. Ensure that specialty packaging is on hand for retail sales. The packaging must be shipped directly to the stores from the vendor.

* Stores must not inventory the packaging materials. Stores must maintain a 50-day supply of specialty packaging materials. Stores must reorder packaging materials as needed.

* Retail store customers must pay full retail price, Resellers must receive a 10 percent discount off the list price.

- Question List (61q)

- Question 1: A company uses Dynamics 365 Supply Chain Management. The fin...

- Question 2: A company receives a large quantity of inventory into the wa...

- Question 3: You need to configure settlement reports for the finance tea...

- Question 4: Note: This question is part of a series of questions that pr...

- Question 5: You are the warehouse manager at a large distribution compan...

- Question 6: You are a functional consultant for a company named Contoso ...

- Question 7: Note: This question is part of a series of questions that pr...

- Question 8: A company implements Dynamics 365 Supply Chain Management. T...

- Question 9: A company plans to implement Dynamics 365 for Finance and Op...

- Question 10: You are the warehouse manager at a distribution center. In t...

- Question 11: Note: This question is part of a series of questions that pr...

- Question 12: Note: This question is part of a series of questions that pr...

- Question 13: You need to set up testing for brakes to meet the operations...

- Question 14: A company is implementing sales order functionality in Dynam...

- Question 15: A company uses Dynamics 365 Supply Chain Management. The com...

- Question 16: Employee 1 needs to set up the new items for the product lin...

- Question 17: A company sells licensed products. You must pay the licensor...

- Question 18: A company orders parts from a vendor. The vendor frequently ...

- Question 19: Note: This question is part of a series of questions that pr...

- Question 20: You are a functional consultant for a company named Contoso ...

- Question 21: Note: This question is part of a series of questions that pr...

- Question 22: You need to configure the system to support the inventory co...

- Question 23: A company implements warehouse locations in Dynamics 365 Sup...

- Question 24: A warehouse uses mobile devices for locating products. Produ...

- Question 25: You are the inventory manager at a large distribution compan...

- Question 26: You are configuring pricing for a new item. Wholesale custom...

- Question 27: A company manufactures and sells speaker boxes. The speaker ...

- Question 28: A company is implementing inventory by using Dynamics 365 Su...

- Question 29: A company uses Dynamics 365 Supply Chain Management. Orders ...

- Question 30: A parent company owns two subsidiaries. Some of the products...

- Question 31: You need to configure inventory levels for the retail stores...

- Question 32: Negotiations with the vendor are complete. You need to set u...

- Question 33: A company implements Dynamics 365 Sales to manage sales pros...

- Question 34: You are implementing Dynamics 365 Supply Chain Management fo...

- Question 35: A company is implementing sales order functionality in Dynam...

- Question 36: You need to configure the system to meet the metric requirem...

- Question 37: A company must ship product from one warehouse, receive it i...

- Question 38: A company plans to use warehouse management and dock appoint...

- Question 39: You need to configure the system to support the pottery prod...

- Question 40: You need to configure the structure for the new line of perf...

- Question 41: A company uses the Dynamics 365 for Finance and Operations W...

- Question 42: You are the sales manager at a distribution company. You hav...

- Question 43: A company uses several freight carriers. Freight is calculat...

- Question 44: You need to identify the cause for the inventory issue repor...

- Question 45: A company needs to stock inventory in their warehouse. Inbou...

- Question 46: A company operates a chain of retail coffee shops and a dist...

- Question 47: You are implementing warehousing in Dynamics 365 for Finance...

- Question 48: A company has several vendors who require 1099s. You need to...

- Question 49: During a company's busy season, the sales team experiences m...

- Question 50: Note: This question is part of a series of questions that pr...

- Question 51: A company uses Dynamics 365 for Finance and Operations. An e...

- Question 52: A company uses Dynamics 365 Supply Chain Management for wave...

- Question 53: You need to set up the procurement category hierarchy in acc...

- Question 54: A company implements the Dynamics 365 Supply Chain Managemen...

- Question 55: A warehouse picks and ships product. The warehouse completes...

- Question 56: A company creates several item costing versions. All new and...

- Question 57: A company plans to use the warehouse mobile app for cluster ...

- Question 58: Note: This question is part of a series of questions that pr...

- Question 59: A company uses outside carrier services for inbound and outb...

- Question 60: You are the materials manager at a distribution company. You...

- Question 61: You are the logistics manager at a distribution company. You...